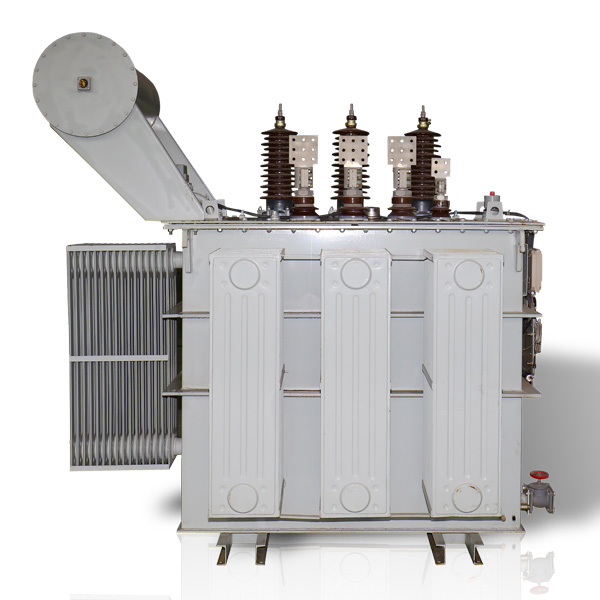

S13-M-30-2500/10 Fully Sealed Distribution Transformer

◇ Three-phase planar coil core fully sealed distribution transformer capacity range 30kVA~1000kVA, a total of 15 varieties.

◇ The iron core is a three-phase three-column inner and outer frame rolling structure. High degree of mechanization.

◇ The high and low voltage coils are continuously wound on the iron core column, with good concentricity and tight coils.

◇ The main technical and economic indicators have reached the international advanced level of similar products.

Description

Scope of Application

◇ Three-phase planar coil core fully sealed distribution transformer capacity range 30kVA~1000kVA, a total of 15 varieties.

◇ The iron core is a three-phase three-column inner and outer frame rolling structure. High degree of mechanization.

◇ The high and low voltage coils are continuously wound on the iron core column, with good concentricity and tight coils.

◇ The main technical and economic indicators have reached the international advanced level of similar products.

Model Meaning

Execution Standards

◇ GB1094.1~2-2013 power transformer

◇ GB1094.3-2003 power transformer

◇ GB/T1094.4-2005 Power transformer

◇ GB1094.5-2008 power transformer

◇ GB/T6451-2015 Technical parameters and requirements of three-phase oil-immersed power transformer

◇ International standard IEC76

◇ GB/T25289-2010 Technical parameters and requirements of 20kV oil-immersed power transformer

Performance Characteristics

Compared with the “9” type transformer, the no-load loss of this transformer is reduced by about 30% on average. Compared with JB/T10088-1999 standard, the noise is small, and the noise is reduced by about 7dB. The temperature rise of the oil level and high and low pressure windings is about 20K-13K lower than the temperature rise limit, and there is a certain overload capacity. Strong resistance to short circuits and high reliability.

Structural Features

Iron core: three-phase three-column inner and outer frame rolling structure, the core column is a multi-step stepped circular section; After the core is rolled, the stress is removed by vacuum annealing; grooved bending clamps, pulling screw tensioner body; The surface of the iron core is coated with special glue to ensure that the iron core does not deform and rust.

Winding and body: low-voltage winding is 1~6 wires wound four-layer or double-layer cylindrical (500kVA and below) or spiral (630kVA and above) winding; The wires are drawn from oxygen-free copper; The interlayer insulation of high and low voltage windings is Linger dispensing paper; The oil gap between the axial oil passage of the high pressure winding and the main airway between high and low pressure is the structure of the brace curtain; The yoke insulation and the trapezoidal pad are integrated to evenly compress the body; The body adopts a new hanging plate positioning structure, longitudinal and transverse positioning to ensure that the body is stable and not displaced.

Fuel tank: corrugated oil tank sealed structure, no oil leakage, maintenance-free.

Main Technical Parameters

S13 6kV, 10kV class Type 13 oil-immersed non-excitation voltage regulation distribution transformer no-load loss and load loss

Note: 1. The load loss value before the slash in the table applies to Dyn11 or Yzn11 coupling group, and the load loss value after the slash applies to Yyn0 coupling group.

Reviews

There are no reviews yet.