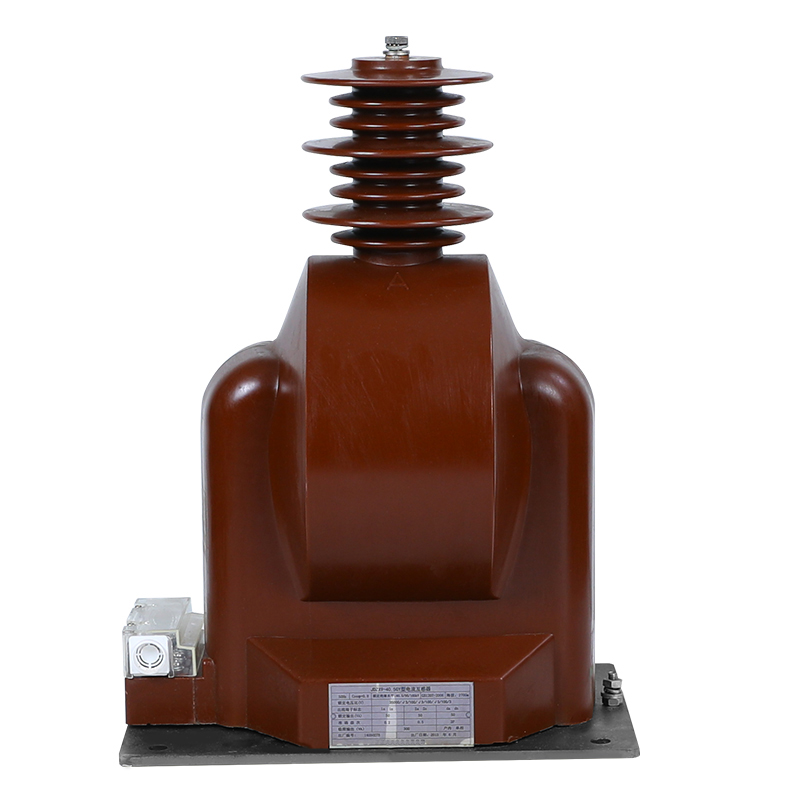

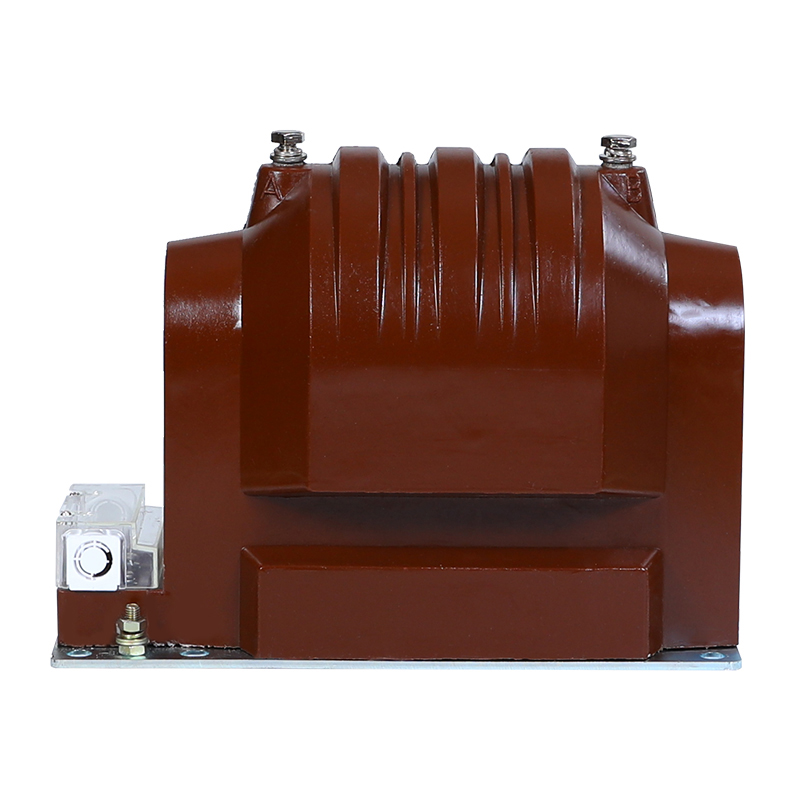

36kV Voltage Transformer

Cold-rolled silicon steel sheet :Because of its excellent magnetic properties, it is widely used as the core material of 36kV voltage transformer in the power industry.

Description

Product Description

Cold-rolled silicon steel sheet :Because of its excellent magnetic properties, it is widely used as the core material of 36kV voltage transformer in the power industry. The cold-rolled silicon steel sheet has the characteristics of high permeability and low core loss, which makes it have excellent energy transfer performance. They are able to efficiently conduct magnetic fields, convert electrical energy into magnetic energy, and transmit it to other electrical devices.

Epoxy resin: Epoxy resin is a widely used material with excellent dielectric properties and mechanical strength. Especially suitable as 36kV voltage transformer primary insulation material. The dielectric properties of epoxy resins refer to their ability to resist the flow of voltage, which is essential to ensure the safe and efficient operation of electrical equipment. Due to its high dielectric strength, epoxy resins can withstand high voltage levels without breaking down, making them ideal for voltage transformer insulation.

In addition to its dielectric properties, epoxy resin also offers exceptional mechanical strength. It has a high tensile strength, which means it can withstand significant mechanical stress without deforming or breaking. This makes it highly reliable in protecting internal components of voltage transformers from external forces and vibrations.

Epoxy casting is the epoxy resin poured into the mold to provide reliable insulation for the voltage transformer. The casting process ensures a uniform and seamless insulation layer that effectively prevents electrical breakdown and leakage. In addition, the insulation also blocks moisture, dust, chemicals and other environmental factors, further enhancing the protection of internal components. This manufacturing method guarantees the quality and reliability of the castings, making it one of the commonly used insulation materials in the power industry.

Copper : Copper conductors are typically used for windings in 36kV voltage transformer. These materials offer high electrical conductivity and mechanical durability, enabling efficient transmission of current signals while withstanding operational stresses.

Product Superiority

Our product plating of screws and bottom plate reaches 8um/min, which is more moisture-proof and rust-proof. The gloss is better.

| 1. | Application | Metering |

| 2. | 1nstallation | Indoor |

| 3. | Construction | Dry type Epoxy Resin Cast |

| 4. | Insulation | Cast Resin |

| 5. | Number of Phase | Single |

| 6. | Rated Frequency | 50 Hz |

| 7. | System Primary Rated Voltage | 33 kV Phase to Phase |

| 8. | Maximum System Voltage | 36 kV Phase to Phase |

| 9. | Systen Earthing | Effectively earthed |

| 10. | Basic Insulation Level (1.2/50 u sec. | 170 KV |

| 11. | Power Frequency Withstand Voltage (1 min.50Hz) | 70 KV |

| 12.13. | Ratio:11kV FeederPrimary | 400/5ASingle Winding |

| 14. | Secondary | Single Winding |

| 15. | Accuraoy Class | 0.2/0.2S for Measurement |

| 16. | Burdena)for Measurement | 10-15 VA |

| 17. | Short Time Current Rating | Minimum 80 kA for 1 Sec |

| 18. | Extended Curent Rating | 120%of Rated Current |

| 19. | Creepage Distance | 30 mm/KV(minimum) |

| 20. | Standard | Design, Manufacture,Testing,Installationand Performance shall be in accordance tothe latest editions of IEC 61869-1 &IEC61869-2 |

Reviews

There are no reviews yet.