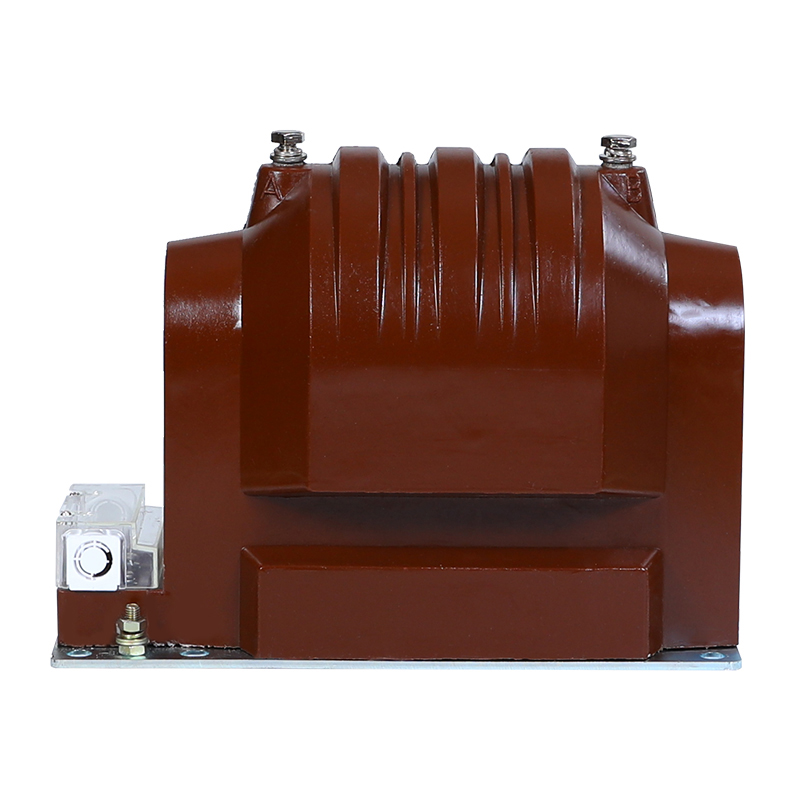

11 kV PT

Cold-Rolled Silicon Steel Sheets: Used as the core material in 11kV PT.These sheets are cold-rolled and possess exceptional magnetic properties, including high permeability and low core loss.

Description

Product Description

Cold-Rolled Silicon Steel Sheets: Used as the core material in 11kV PT.These sheets are cold-rolled and possess exceptional magnetic properties, including high permeability and low core loss. These properties make them well-suited for voltage transformers.

By utilizing cold-rolled silicon steel sheets as the core material, the voltage transformer can achieve efficient energy transfer, thereby enhancing the overall system efficiency. Compared to alternative materials, cold-rolled silicon steel sheets exhibit lower hysteresis loops and magnetization losses, resulting in reduced energy waste and lower power consumption.

Epoxy resin: Epoxy resin has excellent dielectric properties and mechanical strength, is the first choice of 11kV PT insulation material. Epoxy castings provide reliable insulation that protects internal components from electrical breakdown and environmental factors..

Copper : Copper conductors are typically used for windings in 11kV PT. These materials offer high electrical conductivity and mechanical durability, enabling efficient transmission of voltage signals while withstanding operational stresses.

Material (Epoxy Resin ): 11 kV PT use enclosures made of epoxy resin, which has excellent insulation properties and can prevent current or voltage crossing for safe circuit operation. It is also resistant to high temperatures and corrosion, and has good sealing performance for waterproof and moisture-proof capabilities. Epoxy transformers are lighter and easier to install and maintain compared to oil-immersed transformers.

11 kV PT Superiority

Our product plating of screws and bottom plate reaches 8um/min, which is more moisture-proof and rust-proof. The gloss is better.

| 1. | Application | Metering |

| 2. | Installation | Indoor. |

| 3. | Insulation | Cast Resin |

| 4. | Type | Voltage Induction |

| 5. | Construction | Dry type Epoxy Resin Cast |

| 6. | Number of Phase | Singe Phase(1 set=3 Nos.) |

| 7. | Frequency | 50 Hz |

| 8. | Mounting Mounted | Supporting on Gantry Structure Mounted |

| 9. | System Primary Rated Voltage | 11 kV(Phase to Phase) |

| 10. | System Primary Maximum Voltage | 12 kV (Phase to Phase) |

| 11. | System Earthlings | Effectively earthed |

| 12. | Basic Insulation (Impulse withstandVoltage) | 75 kV |

| 13. | Power Frequency Withstand Voltage | 28 kV |

| 14. | The neutral end of primary winding,fordirect connection to ground | Insulated to withstand the 10 kVlow frequency test. |

| 15. | Type of Secondary Winding | Single Winding |

| 16. | Transformation Ratio | 11 kV//3/0.11 kV/3 |

| 17. | Creepage Distance | 25mm/kV(minimum) |

| 18. | Rated Secondary Burden | 7.5 to 10 VA |

| 19. | Voltage limit factor | 1.2 continuous and 1.5 for 30 Seconds |

| 20. | Class of Accuracy | 0.2 for metering. |

| 21. | Standard | Design, Manufacture, Testing, Installation andPerformance shall be in accordance to the latesteditions of IEC 61869-1 & IEC 61869-3. |

Reviews

There are no reviews yet.